The Engineering and Science of Comfort.

Foam is actually a feat of chemistry and engineering.

If you’re not in the foam industry, it might be easy to assume that foam is, well, just foam. One feel, all the same. However, since we’ve been working with foam since its commercial inception in 1952, we can assure you that isn’t the case.

Dive into the different properties of foam and the science behind them.

-

Feel and Structure

The feel of a given piece of foam is a result of its structure, its make-up. In other words, the chemistry of the material determines how it responds to weight and pressure.

-

Durability

The measure of durability in foam revolves around one concept: density. The denser the foam, the more material went into making it, which in turn translates to a longer lasting product.

-

Cooling

One common concern with foam mattresses, born from their early days on the market, is that they will sleep hot. Fortunately, advancements in cooling technology have come a long way and each of our customized mattress constructions is designed to keep your body temperature at an ideal level the whole night through.

We’re Makers

Feel & Structure

What Type of Foam Is It?

For our purposes, we're going to look at a common spectrum of foams applied within in the bedding industry: the spectrum of resiliency. What is resiliency, you ask? It is simply how quickly the material recovers or springs back into shape, its elasticity. In the world of comfort, it can be summarized as bounce, or lack thereof.

Memory Foam

On one end of the spectrum, we have the belle of the foam ball: memory foam, otherwise known as viscoelastic foam. Memory foam has low resiliency and has become famous for its soft, slow recovery and body-contouring, pressure-relieving properties (if you’re imagining someone jumping on a bed with a wine glass, you’re on the right track). While it can be ideal for side-sleepers or anyone seeking pressure relief, preference plays a large part in its application.

Some people love it, swear by it, would never sleep on anything else, and we’ve got their options covered. Other people dislike the “sunken-in” feeling that the first camp prefers. For this crowd, we’re glad to report that there are plenty of other options; memory foam is just one end of the spectrum. Interesting historical fact: memory foam was invented under a NASA contract in the 1970’s.

Hybrid Foam

With slightly more bounce and resiliency than memory foam and more pressure relief than high-resiliency foam, hybrid foams are designed to bring you the best of both worlds. A happy medium. If you don’t have a preference either way, some combination of this material may be just the stuff for you. It’s versatile, comfortable, and has found its way into many of our constructions due to its all-around high performance.

Moreover, the hybrid foams we use also enjoy a fairly open cell design, which provides a high degree of airflow. Rather than trapping your body heat as you sleep, this design makes your mattress more breathable and helps to sidestep over heating."

High Resiliency (HR) Foam

At the far end of the resiliency spectrum lies the bounciest foam of them of all: latex-like, high-resiliency (HR) foam. Think of this material as “the anti-memory foam.” If you drop a golf ball on it, it’ll spring right back. If you jump on it, you’ll bounce, and that wine glass of yours will surely spill. We refer to it as “latex-like” simply because it is polyurethane foam that has been engineered to mimic the feel and properties of latex foam (which can be very heavy and cost-prohibitive).

While firmness is an entirely different measure of feel, the resilience in HR foams can be ideal for creating a firmer feel in the mid layer or top of a mattress. This makes it well-suited for back-sleepers, but again, individual preference is often the determining factor in its application. If you don’t like the sunken-in, “stuck” feeling that memory foam can bring, or prefer not to have a slow-recovering body imprint behind you when you roll over, this is the foam type for you. Adding it to your mattress construction will bring quick recovery and the high level of bounce that you’re looking for.

Firmness

Within given types of foam, there can be varying levels of firmness. As with the level of resiliency, this is an engineered specification of a given piece of foam. Like the feel of our hybrid foam, but want to go a little softer? You can do so! Many foam types are offered in variations ranging from soft to extra firm.

The firmness of polyurethane foam is measured by a physical property called the Indentation Force Deflection, or IFD. While this can sound quite technical, all it refers to is the number of pounds of weight (or force) required to condense a 4-inch thick sample of the foam to 75% of its original height. Translation? The higher the IFD, the firmer the foam.

One important thing that we often note with foam is that, while IFD is the scientific measure of firmness, the level of resiliency or feel of the foam type can also sometimes play into an individual’s perception of firmness or softness. When it comes to feel, it’s not always apples to apples and, for this reason, we always encourage our customers to try their options prior to purchasing whenever possible. That is the best way to dial things in and people are often surprised by what they like best. Below is a table showing the specifications (IFD included!) of each of our comfort layers.

| Foam Type | Density | IFD |

|---|---|---|

| Copper-Infused Memory Foam | 3 lbs/ft3 | 8 |

| Slow Release Foam | 2.5 lbs/ft3 | 16 |

| Soft Responsive Foam | 2.5 lbs/ft3 | 11 |

| Firm Responsive Foam | 2.9 lbs/ft3 | 15 |

| Latex-Like, High Resiliency Foam | 2.6 lbs/ft3 | 18 |

FIRMNESS ≠ DENSITY

Before moving on, we’d just like to clarify a common misconception. As noted in the table above above, firmness is not the same thing as density when it comes to foam. Two samples can have equal densities and be engineered to have different IFDs. Density is an entirely separate property with its own importance, which we’ll dive into in the next section.

Durability

The measure of durability in foam revolves around one concept: density. The denser the foam, the more material went into making it, which in turn translates to a longer lasting product. Foam density is measured in pounds per cubic foot, which is as straightforward as it sounds. The more weight in a given cubic foot, the higher the quality. More material, longer performance

DENSITY = LBS/FT³

Often times, mattress manufacturers will use quality, high-density foam in the top layer or two of a mattress (the parts you feel), then opt to use low-density, cheap foam in the base-layer of the bed in order to cut costs. Ever seen a foam mattress with a big, body-shaped indent in it? A cheap, low-density base is surely to blame. The foam simply isn’t made to last and will collapse with very little use. Those $200 king-sized mattresses on Amazon? Buyers beware.

To give you an idea of just how much the density of the base-layer or core of a mattress affects its longevity, let’s take a look at some numbers:

1-1.5 lbs/ft³

(cheap)

That $200, 12-inch mattress you found on Amazon? We have bad news: it probably won’t last. After 80,000 compressions (a standard in our testing cycle), foam with a density of 1.5 lbs/ft loses over 5 times as much height as 2.2 lb foam. In other words, with this density of foam, you’ll likely find a body-shaped indent after a short period of time.

1.6-1.8 lbs/ft³

(decent)

Nearly all bed-in-a-box brands today use a base layer of foam in the 1.6-1.8 lb range. This typically is the bar that is used to qualify a mattress as “decent,” and is often the benchmark for assigning a 10-year lifespan to a foam mattress. In fact, almost every major bed-in-a-box company offers some form of a 10-year product guarantee (mattress warranties can be a whole other can of worms, but we won’t get into that here). Overall, not a bad bed, but not exactly the most durable material out there.

Memory Foam Density Comparison

2.8 lbs/ft³

(best)

Any mattress that uses 2.0 lb foam or above in the base layer would qualify as a “high-end” mattress and will likely perform beyond the 10-year mark if taken proper care of. Based on our tests of 80,000 compressions, our 2.8 lb mattress core loses less than 1% of its height. Say goodbye to body indents and hello to comfort that will last you for years to come.

Low-density foam in the base layer is a prevailing problem in the mattress industry and, as the numbers indicate, it will likely leave many people unsatisfied with the performance of their mattress over time.

On the opposite end of the spectrum, there has similarly proven to be negative performance associated with using foam that is too dense in the top layers of a mattress. While this material will surely last, too much density can result in overheating as a result of what has become known as the “oven effect.” Essentially, past a certain point, the level of density may create a totally unbreathable layer, which causes a sleeper’s body heat to be trapped all around them while they sleep.

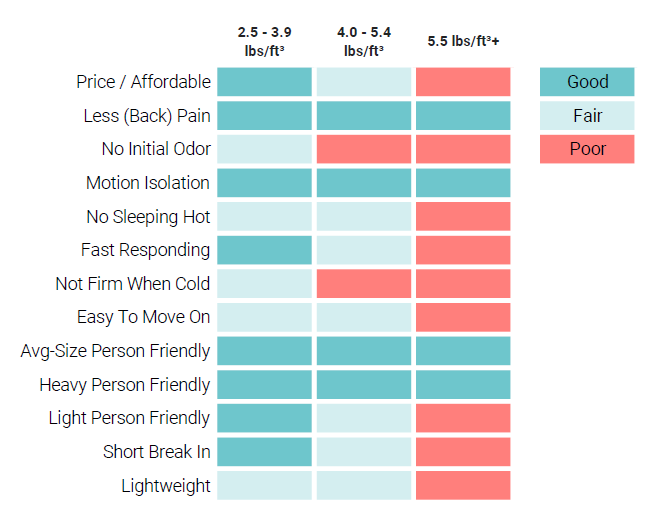

Fortunately, there is a sweet spot: a perfect level of density that is durable enough to last for 10+ years, but won’t create any heat issues (especially when paired with some sort of cooling technology, which we’ll outline in the next section) or any other performance related problems. That sweet spot lies in the 2.5-3.9 lbs/ft³ range, which has become a benchmark and industry standard for memory foams and top layers. Take a look at the following chart, which was compiled from a study of over 7,100 memory foam bed owner experiences, conducted by Sleep Like the Dead, an unbiased sleep-product review source:

As you can see, performance is optimized in the 2.5-3.9 lbs/ft³ range, as well as price. Win, win. All of the foam types we utilize for our top two comfort layers are intentionally selected from within this density range.

In conclusion, density is the true measure of foam durability and quality; a science in and of itself. Many manufacturers intentionally hide this information or flat out refuse to give it; as such, we encourage anyone in need of a mattress to ask the right questions and know the numbers before buying. In an effort to offer true solutions to our customers, we are fully transparent in our manufacturing. Let us know if you have any questions regarding any of the materials we utilize in our customized mattress constructions and we’ll gladly give you answers.

Cooling Technology, For Your Best Night’s Sleep.

One common concern with foam bedding products, born from their early days on the market, is that they will sleep hot. Fortunately, advancements in cooling technology have come a long way and each of our customized mattress constructions is designed to keep your body temperature at an ideal level the whole night through.

Comfort Layers

We refer to the top two layers of our mattress constructions as the comfort layers and, given the fact that we customize our mattress constructions using a wide variety of industry-leading foam types, you’ll find a variety of cooling technologies applied in this section of the mattress. Put simply, we have options.

But how does it work? All of the cooling properties found in our comfort layers rely on either conduction, airflow, or temperature regulation to maintain an ideal temperature.

-

Conduction

Conduction refers to foam types that are infused with highly-conductive material that rapidly disperse your body heat away from you as you sleep. A prime example of this is found in our copper-infused memory foam. It utilizes flecks of actual copper throughout the foam to spread your body head away from the point of contact. Sound like marketing mumbo jumbo? Think again. Check out the demonstration above, showing just how well copper conducts and transfers body heat (enough to quickly melt through an ice cube!) and why it’s easily the most effective cooling option we carry.

-

Air Flow

Airflow is a more straightforward form of cooling technology, but its benefits are undeniable. The dreaded “oven effect” that was unfortunately common with first generation memory foam bedding was simply a result of a lack of breathability. Airflow is the solution and, as such, foam has since been engineered to retain its density and slow-recovering, pressure-relieving qualities while also allowing for airflow. A perfect, proven solution.

-

Temperature Regulation

Temperature regulation is the third and final method of cooling technology, and it comes in several different forms. “Temperature neutral” and “temperature responsive” are two examples of foam types that fall under this category. If a foam is temperature neutral, its firmness will not be affected by temperature. If it is temperature responsive, its feel may change and become more resilient in the presence of body heat. Essentially, temperature regulation refers to how the material in the foam is engineered to respond to changing temperatures. The addition of Phase Change Material to the foam would also fall under the category of temperature regulation, but we will cover that in its own section.

Base Layer

As mentioned in the previous section, airflow is key to cooling. And a layer of our Ventilated Rebound Foam as part of the base layer is designed to provide just that. A best-in-class, open-celled foam type allows air to flow from end to end, giving your body heat a place to go, rather than simply remaining stuck beneath you. When paired with our cooling comfort layers, you’ve got top-to-bottom coverage, allowing you to sleep comfortably cool the whole night through."

Kulkote - Temperature Regulating Technology

KulKote is a phase change material (PCM) and a water-based, polymer coating that is applied to the surface of the foam; in short, it utilizes micro-capsules that continually change phases from a liquid to a solid in order to effectively manage heat energy. In other words, it regulates your temperature while you sleep and keeps your mattress at a perfect, comfortably-cool level all night long (if you’ve ever felt our SoftFlo pillows, you know what we mean).

One feel of a piece of foam with KulKote compared to a piece without is all takes to experience its cooling effects, but don’t just take our word for it. The graphics below show the tangible temperature difference that KulKote brings.

Ready to start?

Start the process that no other mattress website can offer: Making a Custom, Rebuildable Mattress®.